Color can be a tricky subject to understand. At first glance, it seems simple. Primary colors are red, blue, and yellow that create secondary and then tertiary colors when combined with one another, right?

Yes, but also no.

The two most common color processes are CMYK and RGB. The former is used in print mediums while the latter is for screen devices. However, the manner in which they create color is completely different from one another.

Additive vs. Subtractive Color

The two primary color models are additive and subtractive color. The difference between them is how white is created. For additive color, colors are added to make white. For subtractive color, colors are removed to make white.

CMYK

CMYK is an abbreviation for cyan, magenta, yellow, and key. Key is the print name for black ink. These four colors are combined on a percentage scale of 0–100 to create additional colors. CMYK is the method your inkjet or toner printers use. If you carefully examine a printed document under a magnifying glass or jeweler’s loop, you’ll see that the color on the page is created based on a combination of dots in these colors. CMYK is a subtractive color model because printing in ink applies color to your page, while removing the color area creates white.

You may print the same design from different printers and achieve slightly different results as each individual machine has it’s slight variances and nuances—even within the same product line. It’s the same reason why when you purchase paint for your home or office, the advice is to make sure you buy all that you’ll need at once as a second purchase might not match exactly.

A screenshot from Adobe InDesign, showing a CMYK color build. Note that it is a process color and built using percentages between 0 and 100.

But what about when printing on a material that isn’t white? Or, what if you need to print using white ink?

Printing also has spot colors, with the most well-known producer of spot colors being Pantone. Pantone’s color set, known as Pantone Matching System or PMS, is specialty ink in a variety of colors that is created in a manner that’s consistent every single time. If you’ve ever worked with yarn that doesn’t have a dye lot, PMS ink is similar. It’s considered a spot color because the printer will use a dot of specific ink (or, a spot of it) to create the design.

Using Pantone provides options such as white, neon, and metallic ink or colors that can’t be produced with traditional CMYK processes. Additionally, CMYK struggles to produce orange shades, so using a Pantone option can produce better results in that color range.

RGB

RGB is an abbreviation for red, green, blue—much closer to what we normally are taught to be the primary colors. RGB (or a variant) is used by almost every screen to create color by arranging various amounts of each of those three colors within a pixel grid. Additionally, RGB is an additive color model; having a pixel completely filled with all three colors creates white.

Unlike CMYK, RGB is built using varying amounts of the three colors in a range of 0 to 255. Worth noting, these aren’t percentage amounts. But like CMYK, RGB is a process color build as well.

A screenshot from Adobe InDesign, showing a RGB color build. Note that it is a process color and built using values between 0 and 255.

Additional Color Builds

While RGB and CMYK are the primary color methods, there are several other color processes worth noting. Hex color codes are built using six digits consisting of numbers (0–9) and letters (A–F). They start at 00, which is the lowest intensity of color, and go up to FF, which is the highest intensity of color. An additive color process, #000000 is black while #FFFFFF is white. They are not case-sensitive. Hex colors are commonly used in digital spaces.

HSL stands for hue, saturation, and lightness. This additive color model is based on a combination of hue as measured on a 360° color wheel where 0° is red, 120° is green, and 240° is blue with the degrees between being secondary and tertiary colors created with blending. Saturation is measured on a scale of 0–100% with 0% being grey and 100% being the full color. Lastly, lightess is also measured on a scale of 0–100% with 0% being black and 100% being white.

There are more options (HSB, Lab, various RGB spaces such as sRGB or Adobe RGB, etc) but these are the most well-known and used options.

Color Conversion

If you have a color that’s defined using one color method, can you convert it to a different method? Yes, though you may not always have an exact conversion.

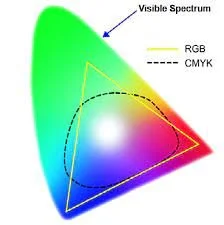

Our universe has a vast array of colors. Within that is a specific spectrum that’s visible to the human eye, based on the three color-receptive cones we have in our eyes. Some animals can see a more limited spectrum of colors than us, and some can see more.

For the spectrum we as humans can see, we haven’t determined how to fully replicate what’s visible to us. RGB is generally a larger spectrum than CMYK, though there are exceptions. In design, it’s advised to create graphics in RGB first to preserve as much color as possible, then convert to CMYK only when a piece is being printed. And while Pantone offers printing options for colors not easily produced in CMYK (as previously mentioned such as fluorescents and metallics), not every Pantone swatch has precise RGB or CMYK conversions.

If you’re working with a client, we highly recommend checking with their marketing team to determine what specific colors they use as well as those color builds within the different color spaces to ensure brand consistency.

An illustration of the visible spectrum of color, with the RGB and CMYK spaces identified.

FileMaker

When working in FileMaker, how can you change the type of color being used or input a custom color? In layout mode, select the object in question and use the appearance panel to select the specific element you’d like to adjust. The fill and stroke panels automatically default to the preselected FileMaker color palette, with a spot to insert a Hex color if you have its code available. If you select the “Other Color...” button, you’ll have greater options for custom imports.

The popup defaults to a color wheel similar to HSL, though it lacks fine-tuning control.

If you go to the second panel within this menu, you have four options for custom color builds:

Greyscale

RGB

CMYK

HSB

All four are labeled as sliders and you can use them to adjust their respective values, but you can also type in specific numbers if that’s easier for you. Given the digital nature of FileMaker, we recommend using RGB or Hex colors, with conversions to CMYK only when necessary for layout that will be printed.

Color can be fickle to work with. However, understanding the basic principles behind how it’s built within different spaces is a massive step towards better understanding it and using it to your advantage.

PK Information is a FileMaker-certified development agency serving the Tampa Bay, Miami Lakes, and Knoxville regions. We believe that software should work the way you do, with business priorities first and technology second.

LEARN MORE

Would you like to learn more about color processes and FileMaker? We’d love to discuss the possibilities with you! Please complete this form and we’ll connect shortly.